Qual é o princípio por trás das máquinas de remoção de ferrugem a laser?

Release time: 2026-01-26

Índice

In the world of industrial maintenance and restoration, the need for effective rust removal is paramount. Traditional methods often involve abrasive techniques or harsh chemicals, which can be damaging to the underlying material. Enter laser rust removal machines, a revolutionary technology that is changing the landscape of surface cleaning. In this article, we will explore the principles behind these machines and how Lisheng, a leader in this field, is making waves with their innovative solutions.

Understanding Laser Rust Removal

Máquinas a laser para remoção de ferrugem utilize high-intensity laser beams to effectively eliminate rust and other contaminants from metal surfaces. The principle behind this technology is relatively straightforward: the laser emits a concentrated beam of light that is absorbed by the rust. This absorption generates heat, causing the rust to expand and eventually disintegrate. The process is precise, allowing for the removal of rust without damaging the underlying metal.

The Science of Laser Technology

At the core of laser rust removal is the science of photonics. Lasers produce a coherent beam of light that can be finely focused, enabling them to target specific areas with incredible accuracy. When the laser beam strikes the rust, the energy is absorbed, leading to a rapid increase in temperature. This thermal shock causes the rust to break apart, making it easy to remove. The process is not only efficient but also environmentally friendly, as it eliminates the need for toxic chemicals and abrasive materials.

Advantages of Laser Rust Removal

One of the most significant advantages of laser rust removal machines is their versatility. They can be used on a variety of surfaces, including steel, aluminum, and even delicate components. Additionally, the precision of the laser allows for selective rust removal, meaning that surrounding areas remain untouched. This is particularly beneficial in industries where maintaining the integrity of the base material is crucial.

Another advantage is the speed of the process. Laser rust removal can be completed in a fraction of the time compared to traditional methods, leading to increased productivity and reduced downtime. Furthermore, the lack of secondary waste generated during the process makes it a cleaner option for industrial applications.

Lisheng: Pioneering Laser Rust Removal Solutions

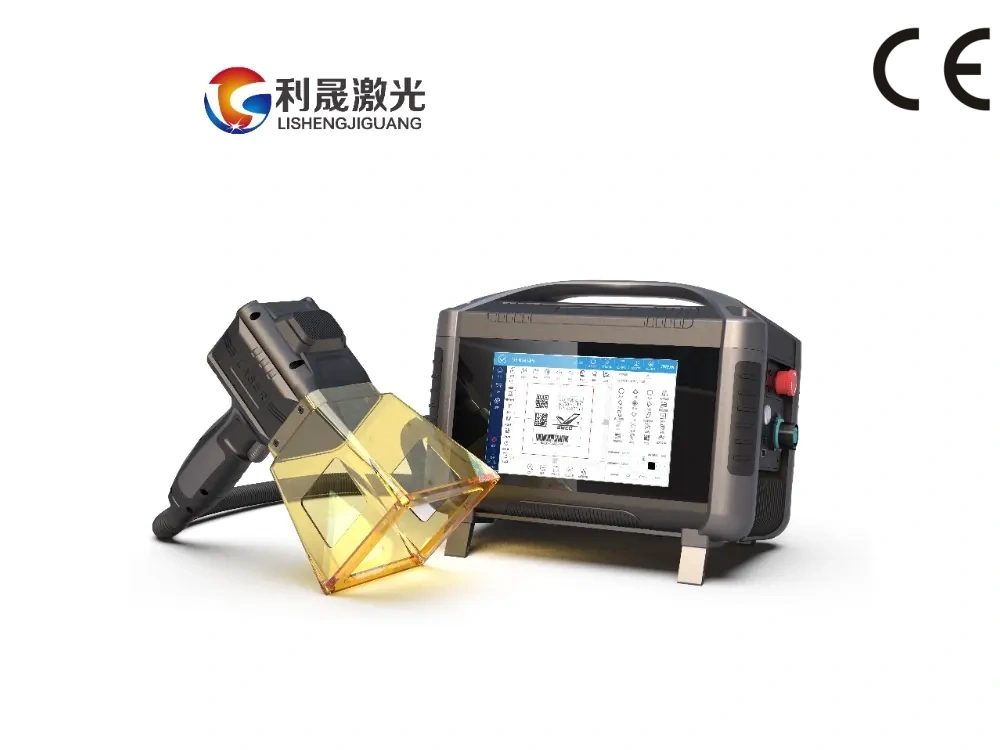

Lisheng is at the forefront of laser rust removal technology, offering a range of machines designed to meet the diverse needs of various industries. With a commitment to innovation and quality, Lisheng has developed state-of-the-art laser systems that are not only effective but also user-friendly. Their machines are equipped with advanced features that enhance performance and ensure safety during operation.

The company prides itself on its customer-centric approach, providing tailored solutions that cater to specific requirements. Whether it’s for automotive, aerospace, or manufacturing applications, Lisheng’s laser rust removal machines are engineered to deliver exceptional results.

In conclusion, laser rust removal machines represent a significant advancement in the field of surface cleaning. By harnessing the power of laser technology, these machines offer a precise, efficient, and environmentally friendly solution for rust removal. Lisheng stands out as a leader in this innovative space, providing high-quality machines that meet the demands of modern industries. As the need for effective rust removal continues to grow, Lisheng is poised to lead the charge with their cutting-edge technology and commitment to excellence. For those looking to enhance their maintenance processes, investing in Lisheng’s laser rust removal machines is a step towards a cleaner, more efficient future.