Как работает лазерный маркировочный станок?

Release time: 2026-01-26

Оглавление

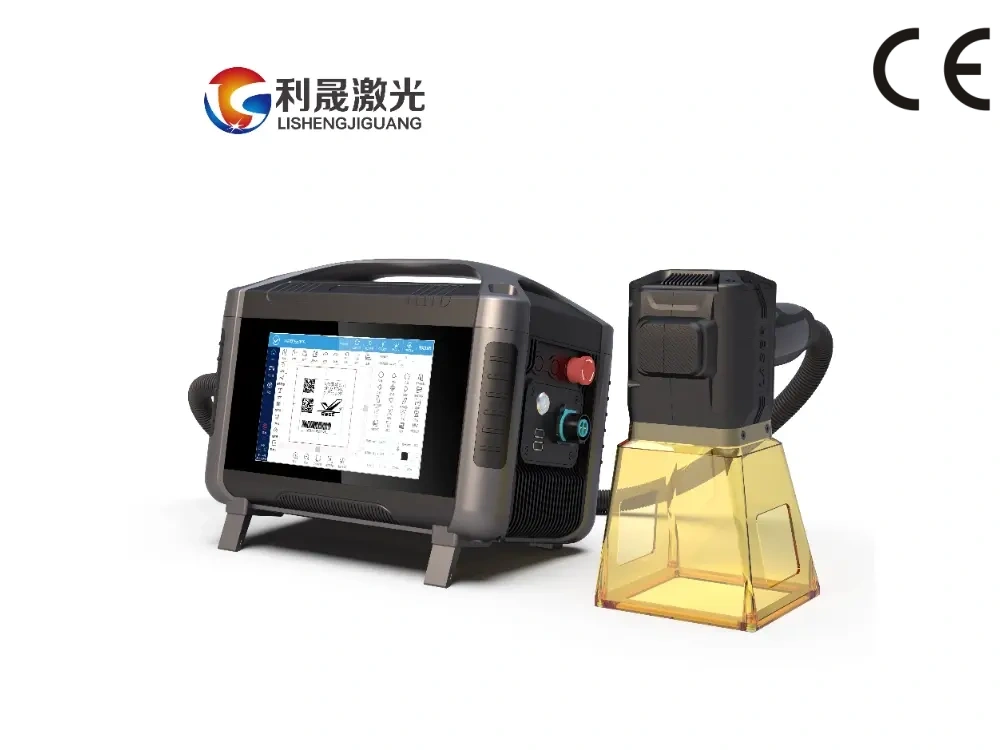

If you walk through almost any modern factory—whether it’s electronics, automotive parts, medical devices, or metal fabrication—you’ll likely see laser markings everywhere. Serial numbers, logos, barcodes, QR codes, and traceability marks are often created by laser marking machines. But how does a лазерный маркировочный станок actually work, and why has it become the preferred solution for permanent marking?

As a manufacturer working closely with real production environments, Lisheng Laser often gets this question from customers who want more than textbook explanations. Let’s break it down in a practical, shop-floor-friendly way.

From Light to Mark: The Core Working Principle

At its core, a laser marking machine uses a highly focused beam of light to interact with the surface of a material. Unlike ink printing or mechanical engraving, laser marking is a non-contact process. That means no tool wear, no consumables, and very little maintenance over time.

Inside the machine, the laser source generates a high-energy beam. This beam is guided through optical components—mirrors and lenses—that focus it down to a very small spot. When that focused beam hits the material surface, it delivers energy in a controlled way, changing the surface characteristics.

Depending on the material and laser settings, this interaction can cause:

- Color change (common on stainless steel and plastics)

- Surface oxidation

- Micro-engraving or etching

- Material removal at a very shallow depth

The key point is precision. The laser doesn’t “burn” randomly—it follows digital instructions with micron-level accuracy.

How Designs Become Laser Marks

In real production, operators don’t manually guide the laser. The marking process starts with design files, often created in CAD or vector-based software. Text, logos, serial numbers, and variable data are imported into the laser control system.

Galvanometer scanners—fast-moving mirrors inside the marking head—direct the laser beam across the surface at high speed. This is why laser marking can handle complex patterns, fine fonts, and high-density QR codes without slowing down the production line.

For manufacturers dealing with traceability requirements, this digital control also allows seamless integration with MES or ERP systems. Serial numbers can change automatically, batch by batch, without stopping the machine.

Different Materials, Different Laser Reactions

One reason laser marking machines are so widely used is their flexibility. Metals, plastics, ceramics, and coated surfaces—each reacts differently to laser energy.

For example:

- Fiber lasers are commonly used for metals like steel, aluminum, brass, and titanium.

- CO₂ lasers are often chosen for plastics, wood, and packaging materials.

- UV lasers work well for delicate components where minimal heat impact is critical, such as electronics, glass, and medical parts.

In real workshops, choosing the right laser type isn’t about trends—it’s about matching wavelength and power to the material and marking requirement.

Why Factories Prefer Laser Marking

From an operational perspective, laser marking machines offer clear advantages. Marks are permanent and resistant to wear, chemicals, and heat. There’s no ink to refill, no molds to replace, and no downtime for consumables.

For companies exporting products globally, laser marking also supports compliance. Clear, durable markings help meet regulatory standards and reduce after-sales disputes related to traceability.

At Lisheng Laser, many customers tell us the same thing: once laser marking is integrated into their workflow, it quietly becomes one of the most reliable stations on the line.

FAQ: Common Questions About Laser Marking Machines

Does laser marking damage the material?

When properly configured, laser marking only affects the surface layer. Structural integrity remains unchanged, which is why it’s widely used for precision components.

Is laser marking suitable for high-volume production?

Yes. With fast scanning speeds and automation options, laser marking machines are commonly used in 24/7 production environments.

Can laser marks fade over time?

Laser marks are generally permanent. They resist abrasion, chemicals, and UV exposure far better than printed or ink-based markings.

A Practical Tool, Not Just Advanced Technology

While laser marking technology may sound complex, its value on the factory floor is simple: consistency, clarity, and control. Understanding how a laser marking machine works helps manufacturers choose the right system and get the most out of it.

As a dedicated laser equipment manufacturer, Lisheng Laser focuses on building machines that fit real production needs—not just lab conditions. When the technology works quietly in the background and delivers reliable marks every time, that’s when it’s doing its job best.